The industrial boiler is an energy conversion facility which uses the heat energy released by the combustion of fuel to heat working fluid or other fluids to a certain parameter. The selection of industrial boilers plays an important role in maximizing the overall efficiency of industrial facilities.

It is important to consider the actual production needs when selecting an industrial boiler. The needs will determine the following three factors: 1. The types of industrial boilers; 2. The fuel of industrial boilers; 3. The combustion methods of industrial boilers.

The water tube boiler and the fire tube boilerare two most common industrial boilers. are two most common industrial boilers.

Capacity:1-20 t/h

Pressure:0.7-2 Mpa

In a fire tube boiler, the threaded smoke tubes are surrounded by water. While passing through the threaded smoke tubes, the high temperature flue gas heats the water or vapour and ultimately produces steam or hot water.

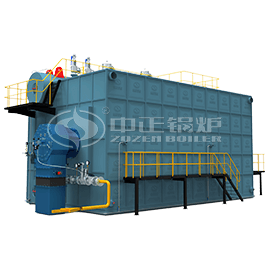

Capacity: 20-110 t/h

Pressure: 1.25-5.3 Mpa

The operation mode of a water tube boiler is exactly the opposite of that of a fire tube boiler. A water tube boiler is such a kind of boiler where the water is heated inside tubes and is surrounded by the hot gas.

It is also important to pay attention to the boiler fuel when selecting an industrial boiler. Some common fuel types include:

Coal is the standard fuel source of industrial boilers, such as the bituminous coal, anthracite coal, lean coal, lignite, etc. The fuel costs of coal is relatively low. However, accompanied by high emissions, the coal-fired boiler usually requires to adopt a dust collector. is the standard fuel source of industrial boilers, such as the bituminous coal, anthracite coal, lean coal, lignite, etc. The fuel costs of coal is relatively low. However, accompanied by high emissions, the coal-fired boiler usually requires to adopt a dust collector.

Capacity:2-20 t/h

Pressure:1-2.5 Mpa

Capacity:4-35 t/h

Pressure:1-2.5 Mpa

Capacity:20-75 t/h

Pressure:1.25-5.4 Mpa

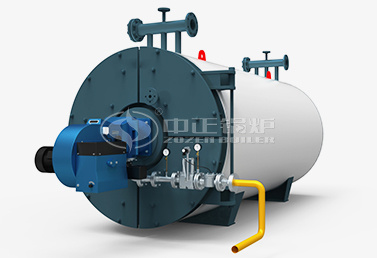

Liquid or gas fuelssuch as the natural gas, biogas, blast furnace gas, liquefied petroleum gas, diesel and light oil, are cleaner than other forms of fuel. With a high heat energy ratio, the liquid and gas fuels are highly flammable. such as the natural gas, biogas, blast furnace gas, liquefied petroleum gas, diesel and light oil, are cleaner than other forms of fuel. With a high heat energy ratio, the liquid and gas fuels are highly flammable.

Capacity:1-20 t/h

Pressure:0.7-2 Mpa

Capacity: 20-110 t/h

Pressure: 1.25-5.3 Mpa

Capacity: 700-14000 KW

Pressure: 0.8-1.0 Mpa

Biomass fuels refer to combustible biomass particles, wood chips, rice husks, straw, corn cobs, etc. With features of low carbon, renewability and cleanness, the biomass energy is an important renewable energy source. refer to combustible biomass particles, wood chips, rice husks, straw, corn cobs, etc. With features of low carbon, renewability and cleanness, the biomass energy is an important renewable energy source.

Capacity:2-20 t/h

Pressure:1-2.5 Mpa

Capacity:4-35 t/h

Pressure:1-2.5 Mpa

Capacity:20-75 t/h

Pressure:1.25-5.4 Mpa

The thermal efficiency of industrial boilers is related to the combustion method. The grate combustion, chamber combustion, fluidized bed combustion and thermal oil heaters are four common combustion methods. are four common combustion methods.

In grate combustion, the fuel is distributed on a grate with a certain thickness for combustion. The chain grate and the reciprocating grate are two common types of grate combustion. The ZOZEN DZL series coal-fired (biomass-fired) boilers, SZL series coal fired (biomass-fired) boilers and DHL series coal-fired (biomass-fired) boilers all adopt the grate combustion.

In chamber combustion, the fuel is sprayed into the furnace with air and burned in suspension. The combustion method of ZOZEN WNS series gas-fired (oil-fired) boilers and SZS series gas-fired (oil-fired) boilers belongs to the chamber combustion. It is generally applicable to the liquid fuel and gas fuel.

In boiling combustion, the fuel is burned in a fluidized boiling state on the boiling bed under the action of air at an appropriate flow rate. ZOZEN circulating fluidized bed boilers have features of wide fuel adaptability, high thermal efficiency, good environmental protection effects, etc.

Thermal oil heaters generally use coal, oil and gas as fuel and use oil as the heat medium. By the utilization of a thermal oil circulating oil pump, the heat medium oil is forced to circulate in the liquid phase and transfer the heat energy to the heat consuming equipment. The boilers are mainly used for low-pressure and high-temperature heating.

Capacity: 35-100 t/h

Pressure: 1.25 - 5.3 Mpa

Capacity : 10-100 t/h

Pressure : 1.25 - 2.5 Mpa

Capacity : 700-14000 KW

Pressure : 0.8-1.0 Mpa

Capacity : 1400-29000 KW

Pressure : 0.8-1.0 Mpa

ZOZEN is always ready to provide cost-effective solutions that cater to customer needs, helping customers to improve operating efficiency and save costs.

WhatsApp: +86 18861589035

WeChat: +86 13506150756

+86188615890356

info@zozen.com

0086-510-68530299